Test Lab Services

Tektronics is proud to provide our clients with test lab services. We have used our considerable experience in the electronic component field and have chosen one of the leading test labs in the country. All component testing is performed by an independent , unbiased test lab. Read below to learn more about the services we can provide.

|

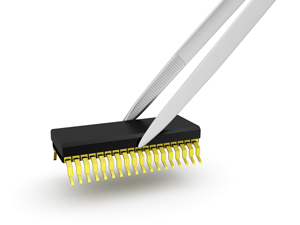

External Visual Inspection

External visual inspection is the process of verifying the attributes of parts such as the component condition, part marking, evidence of a secondary coating, lead conditions, dimensions and surface quality. Visual inspection is performed per SAE AS5553 and MIL-STD-883 Method 2009.9 on sample parts according to the ANSI ASQE Z1.4 Table II−A.

|

|

Surface Chemical Test

This test process will be able to confirm and determine if the device has been remarked or resurfaced. Many counterfeiters use an older date codes or slower speed devices and refurbish them to appear new and marked as a higher grade with a recent date code or as RoHS compliant. Counterfeiters have access to reclaimed, scrapped and excess parts, which are easily available from unauthorized sources. This is considered a destructive test. Re-Surfacing / Re-Marking test are based on AS5553, MIL-STD-202 and JESD22-B107C.

|

|

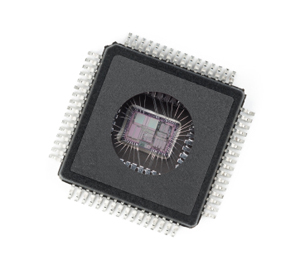

Internal Visual Inspection (Decapsulation)

Decapsulation inspection is a process of verifying the manufacturer die to ensure that it is correct . This is considered a destructive test. We have many different methods to expose the die. Once the die is exposed, the attributes of the die, such as die markings, metallization damage due to ESD or corrosion will be verified. Decapsulation is performed on 1 sample per lot code or date code base on MIL-STD-883, Method 2014.

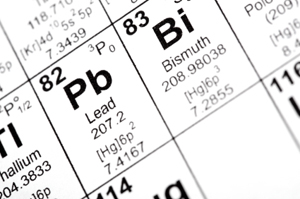

X Ray Fluorescence Spectroscopy (XRF)

XRF can be carried out on the parts to evaluate the material composition of the terminations and the molding compound in order to detect the presence or absence of Pb and other discrepancies with an authentic part. It is a non-destructive test. A complete graph will be provided with a list of substances found. The EU RoHS Directive (2011/65/EU) restricts the maximum allowable levels of lead (Pb), cadmium (Cd), mercury (Hg), hexavalent chromium (Cr6+), polybrominated biphenyl (PBB) and polybrominated diphenyl ether (PBDE) flame retardants to 0.1% or 1000ppm (except for cadmium, which is limited to 0.01% or 100 ppm) by weight of homogeneous material in electrical equipment and electronic products. In order to manufacturer these products within or imports into the European Union, manufacturers are responsible for providing documentation.

|

|

X-Ray Inspection

X-ray inspection is a non-destructive test. It is a process to verify the bond wire connections, die size comparison and ESD damaged. Our typical sample lot check is 5 samples or 100% depending on customer requirements. Counterfeit devices can be determined by comparing the structure of the die to a known good device. Parts should be identical from bond wire location to die size. X-Ray perform base on AS5553 and MIL-STD-883 2012.7

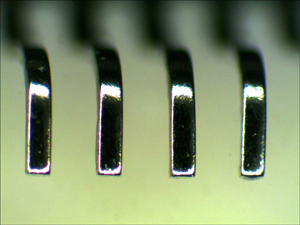

Solderability Test

Solderability is a test to determine if the components will have a soldering issue at the contract manufacturer. Especially with old date code components leads can have oxidation. This will cause components to be unsolderable to the board. As a result you will have mechanical failure which will delay the CM process and increase cost. It is recommended that all lead devices more than two years old be subject to a solderability test.

|

|

|

AC/DC Electrical Test

Our testing services partner offers a wide range of components testing from basic DC limited function to full DC/AC function test at temperature, including up-screening of all type of devices. As a solution provider our engineering team is ready help.

Devices family included:

- Digital, Linear, Memory, and MPU

- Linear IC, Op Amps, and Mixed Logic

- Microprocessors, DSPs, Microcomputers

- Memories, RAM, FPGA, ROM

- Discrete Semiconductors, Transistor, Diode, Zener, SCR or Triac

- Passives capacitors, Resistor, Inductor, Magnetic, Crystal, Filters

|

|

Up-Screening

We have the ability to take commercial (C grade) products and test them at a higher temperature to obtain "I" and "M" grade components. Our Testing Services provide comprehensive electrical and environmental testing of all types of semiconductors. These includes but are not limited to:

- FPGAs

- Microcontrollers

- Microprocessors

- Memories

|

|

|

Baking and Dry-Pack

Many devices are moisture sensitive. Improper packaging can cause major issues for the end user. Moisture induced interface delamination begins with the package absorbing moisture from the environment, which condenses in micropores in polymer materials such as the substrate, attached die, and molding compound. During the PCB assembly process, when the part is exposed to high temperatures associated with the soldering process, popcorning may occur. We can eliminate these problems by baking and then dry-pack all moisture sensitive devices prior to leaving our facility. This process is based on J-STD-033B-1.

|